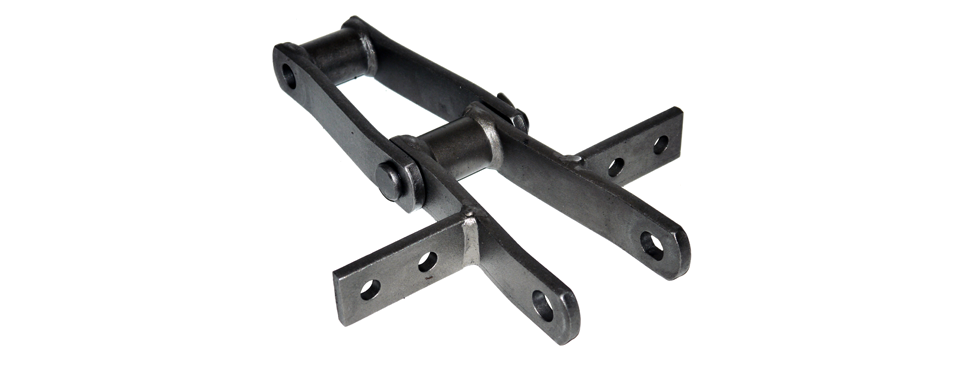

Welded steel chains are of offset sidebar construction and do not have rollers, ideal for high impact and abrasion resistant conveying applications particularly suitable for timber decks and other timber handling conveyors.

Barrels are welded direct to chain sidebars with riveted or cottered pins. Chains can be supplied in the fully heat treated condition with the addition of induction hardened pins and barrels.

This family of chain is extremely versatile and adaptable for many uses offering a huge choice of welded attachments.

On narrow screens you can scroll the following tables horizontally.

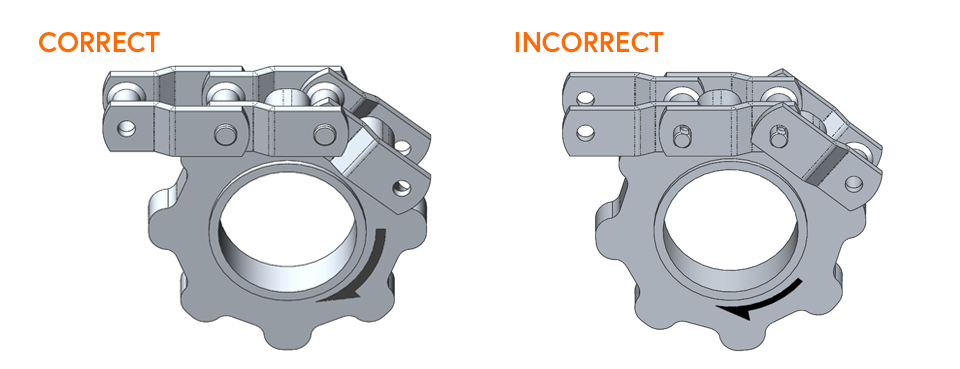

Direction of Travel

To maximise conveyor and elevator chain life the correct direction of travel is important on all offset sidebar cast / bushed chain without rollers.

Chain should work with the open end of the link leading thus, obviating any frictional wear which could take place between the link and the driving sprocket teeth.

This rule applies to any offset sidebar conveyor or elevator chain WITHOUT ROLLERS and all offset sidebar cast or forged link chains.

From the diagram it can be seen that if the closed end of the link leads, then the link itself rotates on the driving tooth as the wheel articulates, whereas, if in the CORRECT position, with the open end of the link leading, the following link to the one actually being driven merely articulates on its pin as the sprocket wheel revolves.

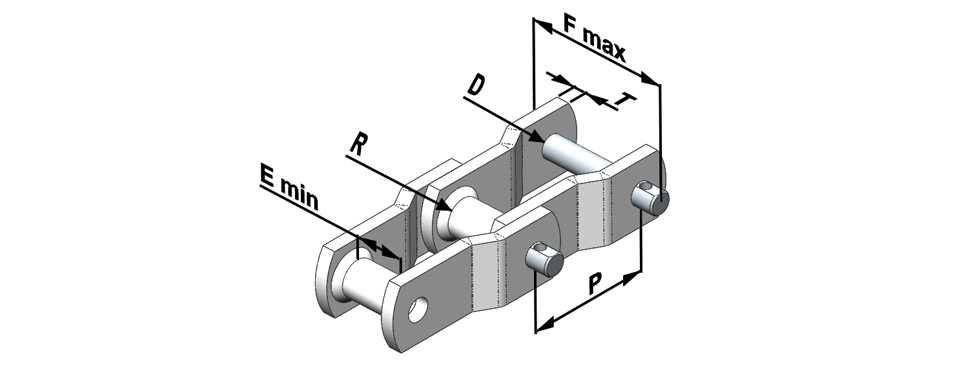

Cranked Chain

| Code | Average Pitch P (mm) | Inner Width E (mm) | Sidebar Thickness S (mm) | Sidebar Height H (mm) | Pin Diameter D (mm) | Pin Length A (mm) | Barrel Dia R (mm) | Overall Length of Barrel F (mm) | Average Weight Kg/m | Min Ult strength Kn |

|---|---|---|---|---|---|---|---|---|---|---|

| WH78 | 66.27 | 25.4 | 6.4 | 31.75 | 12.7 | 75 | 21.34 | 51 | 6.56 | 146.8 |

| WH78XHD | 66.95 | 25.4 | 9.5 | 31.75 | 14.29 | 82 | 25.4 | 50.8 | 9.18 | 163.5 |

| WH82 | 78.1 | 28.58 | 6.4 | 31.75 | 14.29 | 82.3 | 25.4 | 57.15 | 7.22 | 160 |

| WH82XHD | 78.1 | 28.6 | 9.7 | 38.1 | 19.05 | 96.5 | 31.75 | 60.9 | 12.8 | 254 |

| WH124 | 101.6 | 38.1 | 9.7 | 38.1 | 19.05 | 107 | 31.75 | 71.4 | 11.81 | 250 |

| WH124XHD | 103.2 | 38.1 | 12.7 | 50.8 | 25.4 | 119.5 | 44.45 | 76.2 | 21 | 542 |

| WH111 | 120.9 | 57.1 | 9.6 | 38.1 | 19 | 123.9 | 31.7 | 85.8 | 11.94 | 254 |

| WH106 | 152.4 | 38.1 | 9.7 | 38.1 | 19.05 | 107 | 31.75 | 69.85 | 9.84 | 250 |

| WH110 | 152.4 | 47.7 | 9.6 | 38.1 | 19 | 117.3 | 31.7 | 76.2 | 7 | 357 |

| WH106XHD | 153.67 | 38.1 | 12.7 | 50.8 | 25.4 | 120.2 | 44.45 | 76.2 | 18.37 | 542 |

| WH132 | 153.67 | 76.2 | 12.7 | 50.8 | 25.4 | 156 | 44.45 | 112.3 | 21.32 | 542 |

| WH132XHD | 153.67 | 76.2 | 15.88 | 50.8 | 25.4 | 168.86 | 44.45 | 118.8 | 22.63 | 543 |

| WH150 | 153.67 | 76.2 | 12.7 | 63.5 | 25.4 | 156 | 44.5 | 112.3 | 24.27 | 620 |

| WH155 | 153.67 | 73.2 | 12.7 | 63.5 | 28.4 | 158.7 | 41.1 | 111.2 | 28.24 | 771 |

| WH157 | 153.67 | 76.2 | 15.9 | 63.5 | 29.1 | 171 | 44.5 | 117.5 | 30.17 | 820 |

| WH150XHD | 153.67 | 76.2 | 15.7 | 63.5 | 28.4 | 171.4 | 41.1 | 117.3 | 26.17 | 920 |

| WH159 | 155.57 | 69.85 | 15.9 | 76.2 | 31.75 | 170.5 | 50.8 | 117.5 | 37 | 950 |

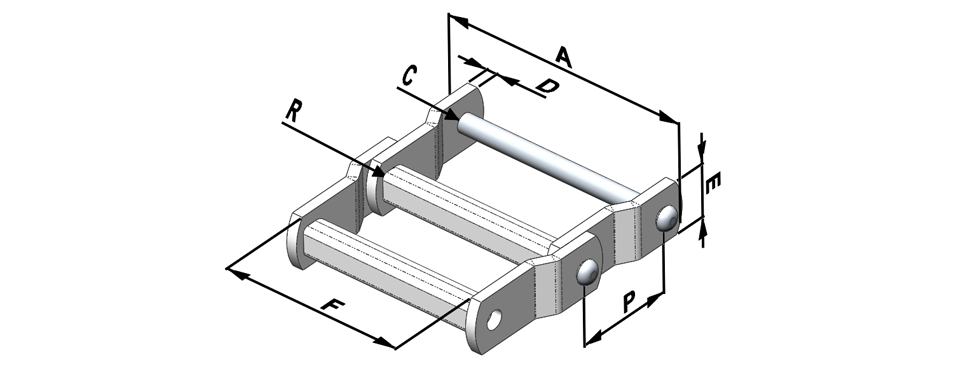

Drag Chain

| Code | Average Pitch P (mm) | Inner Width F (mm) | Sidebar Thickness D (mm) | Sidebar Height E (mm) | Pin Diameter C (mm) | Pin Length A (mm) | Overall Length of Barrel B (mm) | Average Weight Kg/m | Average Ultimate Strength (kgs) |

|---|---|---|---|---|---|---|---|---|---|

| WDH102 | 127 | 162 | 10 | 38.1 | 19.05 | 235 | 197 | 18 | 23133 |

| WDH104 | 152.4 | 104.78 | 10 | 38.1 | 19.05 | 172 | 136.55 | 12 | 23133 |

| WDH110 | 152.4 | 228.6 | 10 | 38.1 | 19.05 | 299 | 260.35 | 18 | 23133 |

| WDH112 | 203.2 | 228.6 | 10 | 38.1 | 19.05 | 299 | 260.35 | 14 | 23133 |

| WDH116 | 203.2 | 330.2 | 10 | 44.45 | 19.05 | 394 | 359 | 21 | 23133 |

| WDH118 | 203.2 | 336.55 | 12.7 | 50.5 | *22.25 | 422 | 359 | 28 | 31752 |

| WDH120 | 152.4 | 222.25 | 12.7 | 50.8 | *22.25 | 304.8 | 260.35 | 28 | 31752 |

| WDH122 | 203.2 | 222.25 | 12.7 | 50.8 | *22.25 | 304.8 | 260.35 | 22 | 31752 |

| WDH480 | 203.2 | 279.4 | 12.7 | 50.8 | *22.25 | 368 | 323.85 | 26 | 31752 |

* also available as 25.4mm

WR = chains have only through hardened rivets

WH = chains have all parts through hardened

WHX = chains have through hardened parts and induction hardened rivets as standard

Riveted construction is standard. Pin and cottered construction can be furnished on a made to order basis.